If you're looking to decorate glass or tumblers and wondering if vinyl wraps vs sublimation wraps are better, we're going to get to the bottom of it today.

There are pros and cons to both vinyl printing and sublimation and deciding which is best will be based on the type of equipment you have, the blanks you have and your personal preference.

Pros and Cons of Vinyl Wraps

Let's first look at vinyl wraps. The biggest benefits of a vinyl wrap, which is essentially a sticker, is that it can be applied to pretty much any type of drinkware surface including glass, stainless steel, or even plastic. The color of the drinkware does not matter it can be clear or it can be black or any color in between.

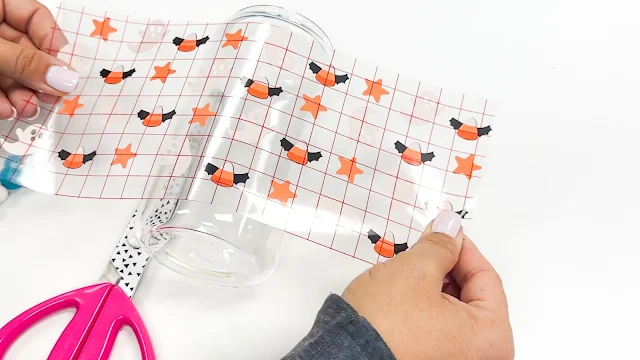

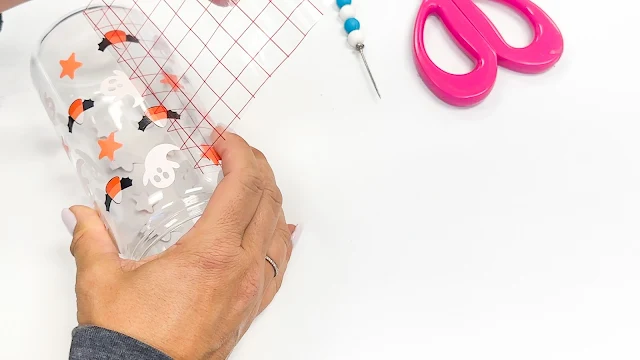

A piece of transfer tape picks up the entire wrap to move the vinyl sticker wrap to the surface.

The wrap is then pressed onto the surface and then the transfer tape or mask is peeled away leaving the vinyl wrap behind.

Downsides to vinyl wraps are both both in how they're made and their durability. Depending on the equipment available, making vinyl wraps can be time consuming to cut, weed, and layer.

If you use a print and cut machine like a Roland BN2-20A or BN2-20 you can both print and cut in one and won't need to layer at all.

However if you're using a Silhouette machine and inkjet printable vinyl to make vinyl wraps you would need to cut all layers of the vinyl, weed them, and then layer before applying to the surface.

As far durability, anything that's stuck onto another surface with adhesive, like a vinyl wrap would be, has the risk of peeling over time with handling and washing.

Pros and Cons of Sublimation Wraps

The benefits of sublimation wraps are they do not require any cutting or weeding and there's no risk of peeling. The sublimation transfer is simply printed onto sublimation paper using a sublimation printer - in this case I used a Sawgrass SG1000.

It's wrapped around the drinkware, heat and pressure are used from either a tumbler press or oven to transfer or infuse the ink into the surface of the substrate.

However, the biggest downside is that special sublimation-ready blanks, that have a poly coating, are required for sublimation wrap transfers.

This means there are a lot more limitations as far as the drinkware that can be used with sublimation wraps - in both material and color. You must not only have poly-coated drinkware, but they must be either white or in the case of sublimation-ready glass they can be clear or frosted.

In this photo below you see the same image was sublimated on the clear glass but a vinyl wrap of the same wrap was applied to the clear glass and blue tumblers.

.png)

No comments

Thanks for leaving a comment! We get several hundred comments a day. While we appreciate every single one of them it's nearly impossible to respond back to all of them, all the time. So... if you could help me by treating these comments like a forum where readers help readers.

In addition, don't forget to look for specific answers by using the Search Box on the blog. If you're still not having any luck, feel free to email me with your question.