The reason DTF or Direct to Film printing, specifically in the smaller desktop size, has become so popular is in part because of sublimation. Both processes are print and press. There is no cutting or weeding required which makes both sublimation and DTF ideal for full color graphics and images.

DTF, however, solves one of sublimation's biggest issues: the inability to apply directly to darks and cottons. But that's just one of several big differences. Read on for more on the differences between sublimation and DTF and which you may want to consider for your small business.

Sublimation Printing

Sublimation printers, like the Sawgrass SG500 or 24" Epson F570, use a special ink printed on sublimation transfer paper to transfer the design onto the fabric or substrate.Sublimation transfers can not only be applied to garments but hard goods such as luggage tags, drinkware, puzzles, and photos panels, as well.

The biggest issue with sublimation printing is the substrate needs to have a high poly count and be light colored. For garments that's at least a 65% polyester blend. Hard goods and substrates need to be sublimation-ready and have a poly coating.

DTF Printing

DTF printing is a relatively new printing technique that has gained popularity because there are no limitations for the color of the garment or the type of fabric including 100% cotton.

In DTF printing, a special ink is used to print the design directly onto a film. DTF powder is then applied to the wet ink and cured. The cured powder creates a waxy-type texture which becomes the adhesive when applied to the garment.

DTF printers, unlike sublimation printers, print white ink. The white ink layer is added behind the full color image allowing the colors to show even when the transfer is applied applied to a dark surface.

DTF transfers are limited to garments and textiles only and can not be used on hard goods like mugs as sublimation transfers can be.

The other downsides to DTF printers, compared to sublimation printing, is the upfront cost and the amount of maintenance they require. The white ink contributes to both. While sublimation printers do not require any maintenance other than to be kept plugged in to automatically cycle, ideally you need to be printing on a DTF printer every day to keep it good working order. In addition there's weekly maintenance needed as well.

Even at the low end, the price to jump into DTF printing is more than sublimation printing by a relatively significant amount.

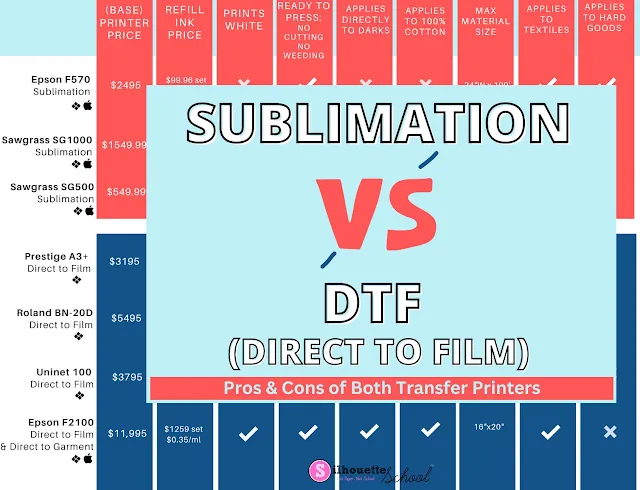

I have put this chart together so you can get a side by side comparison of sublimation vs DTF printing.

DTF vs Sublimation Comparison Chart

I have three sublimation printers and four DTF printers...and have created a lot of content and educational resources around both of them.

To learn more about sublimation and the various sublimation printers this is the best place to start.

To learn more about DTF printing start here.

Get Silhouette School lessons delivered to your email inbox! Select Once Daily or Weekly.

.png)

No comments

Thanks for leaving a comment! We get several hundred comments a day. While we appreciate every single one of them it's nearly impossible to respond back to all of them, all the time. So... if you could help me by treating these comments like a forum where readers help readers.

In addition, don't forget to look for specific answers by using the Search Box on the blog. If you're still not having any luck, feel free to email me with your question.