One is an ecosolvent print and cut machine that can cut everything from vinyl stickers to photos to heat transfers and the other is a 20" DTF printer that prints weedless, cutless direct to film transfers. Read on for the difference between the two 20" Roland desktop printers...and don't forget to sign up to get updates on BN-20D pre orders, tutorials and updates!

The Roland BN-20 and Roland BN-20A are 20" ecosolvent print and cut machines. They use ecosolvent ink to print on a wide variety of materials including vinyl, sticker material, photo paper, heat transfer, banner material, and window cling. The machine then cuts - either kiss cut or die cuts - the image out of the material.

The cut results in a hard edge and on line materials, the materials then needs to be weeded and transferred.

The BN-20D prints direct to film transfers, on the other hand, which are weedless, cutless transfers printed directly onto film. A layer of white ink is then laid over top the full color image to produce an opaque transfer. A curing powder is applied to create the adhesive before the transfer is applied to the garment.

The BN-20 and the BN-20D are as different then as the process and technique. This isn't really a pros and cons list because you're comparing apples to oranges despite what, on the surface, appears to be very similar machines. Really though they are totally different and if you're wondering - do I need both? ...well. They do totally different things so...maybe.

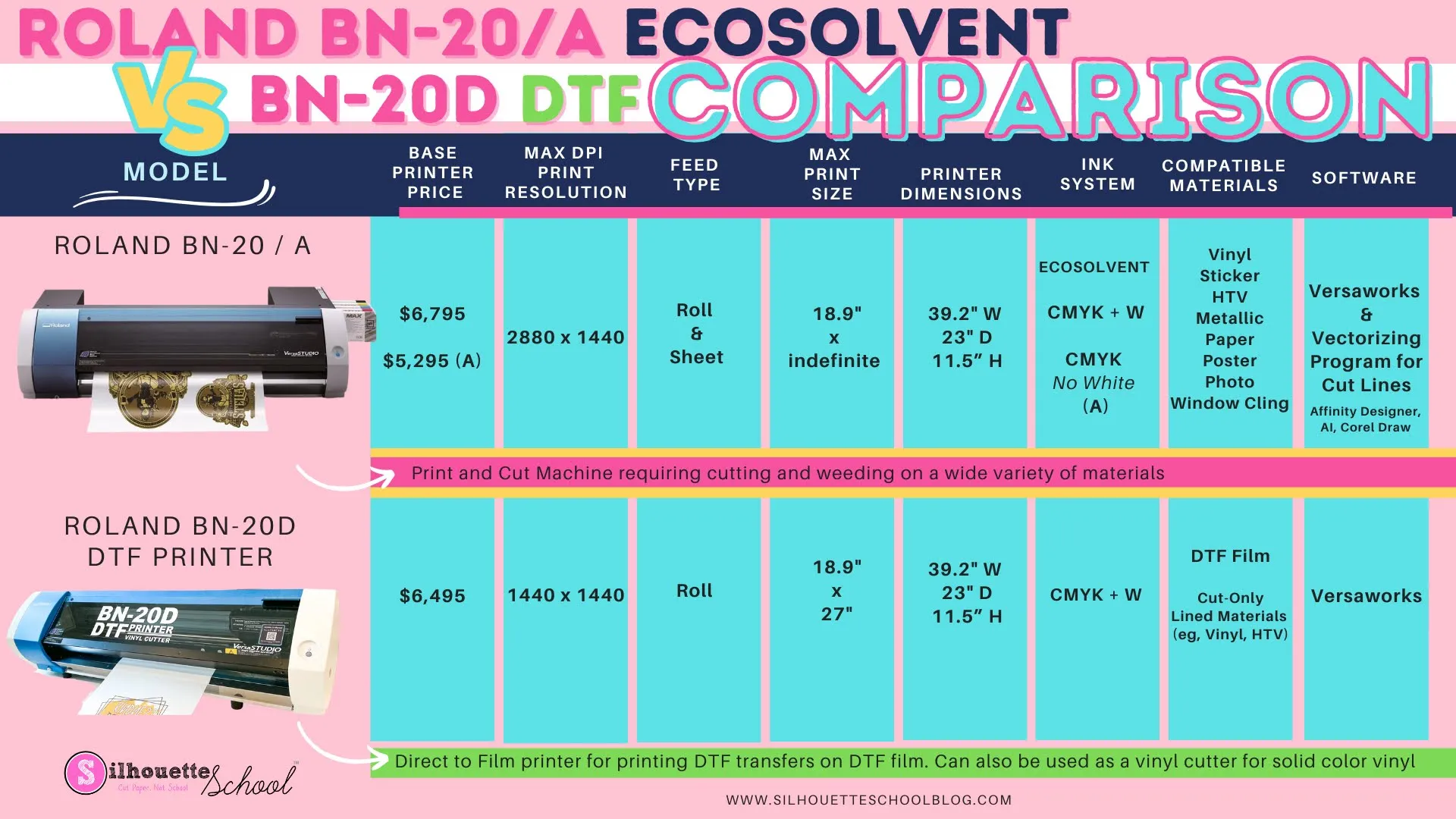

Roland BN-20 and BN-20A vs BN-20D DTF Printer

Let's talk about the similarities first because that list is much shorter.

Both the BN-20 and BN-20D can print CMKY and white ink and result in bright, vibrant colors. (The BN-20A is nearly identical to the BN-20 with the exception it can not print white. For the purposes of this comparison I will refer to both as the BN-20.)

Both the ecosolvent and DTF Roland models can take rolls of media up to 20" wide and both run off Roland Versaworks software.

Both create transfers, that when applied to garments, have a slight hand. Both offer good washability.

Finally, I can't not mention the similarities in the name and appearance...both of which, to me, are far too similar and enough to cause more confusion than necessary. Hence why I put a giant vinyl decal on the front of my DTF model so it would be easier for you to understand which machine I'm using...and when.

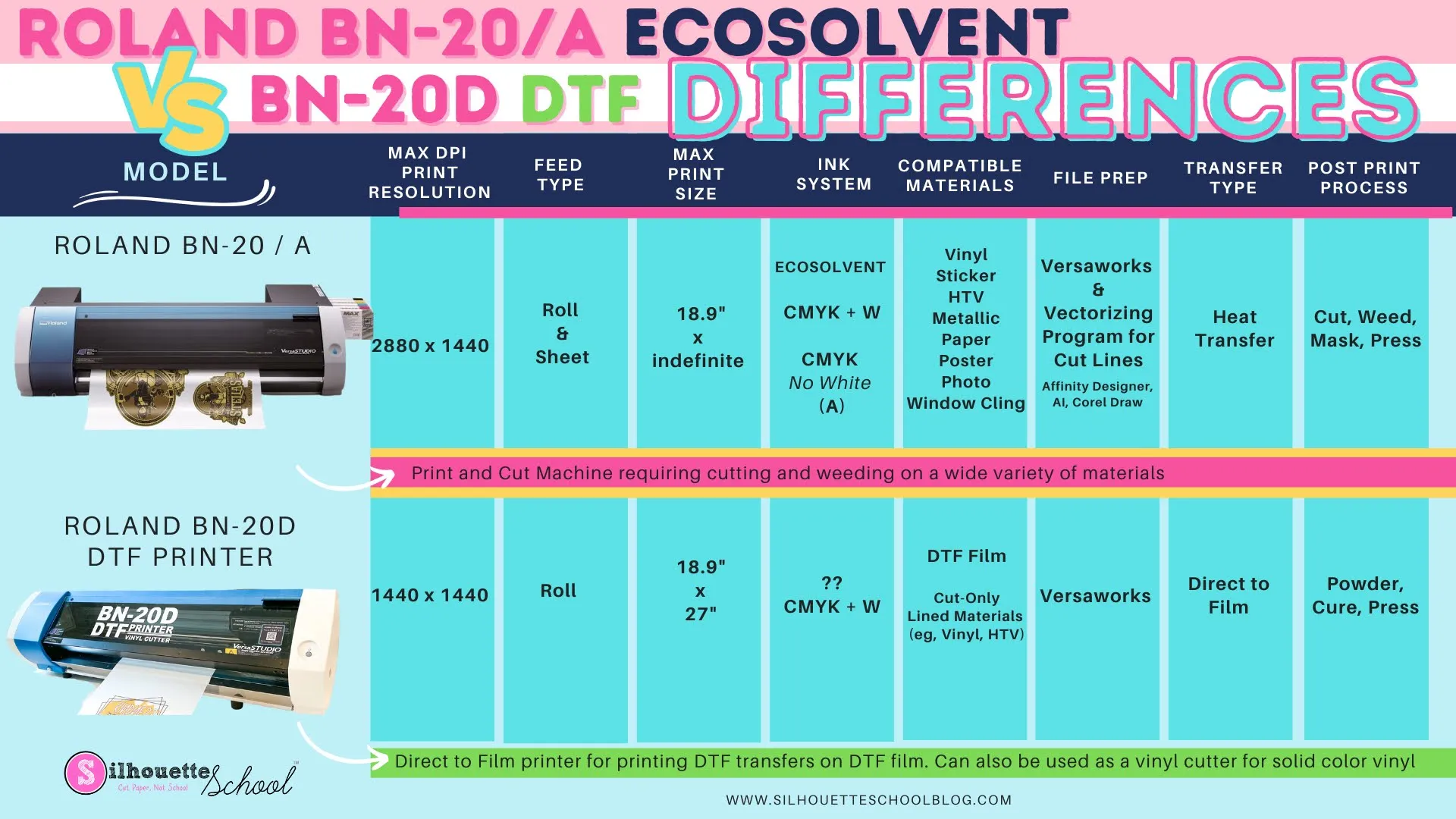

The list of differences between the 20" ecosolvent printer and the 20" desktop DTF printer is much greater so let's take a look.

Ink and Media Type

The Roland BN-20 (And BN-20A) uses ecosolvent ink. Ecosolvent ink is fade and scratch resistant producing high quality graphics.

The Roland BN-20D uses inkjet ink. It has 5 cartridge slots for CMYK and White.

The Roland BN-20 can print on vinyl, paper, sticker and label material, window cling, banner and canvas material and heat transfer along with a wide variety of speciality finishes including glitter and holographic materials.

The Roland BN-20D prints on DTF film. However - it can also double as a vinyl cutter.

Versaworks Software and Image and Graphic Set Up

Both the Roland BN-20 and BN-20D run off the Roland Versaworks rip software. However the file prep and process is different for both machines.

The Roland BN-20 requires the user to add cut lines to the image so Roland Versaworks knows which lines are to be printed and which are to be cut. Adding contour cut lines usually requires a separate software program and can be a time consuming step. It's often the biggest learning curve for new BN-20 and BN-20A users.

DTF images being printed on the BN-20D do not require cut lines as there is no cutting in DTF. However, there is a three step settings process - done completely in Versaworks - that the user will need to go through before printing each DTF transfer.

Printing and Cutting Process

The Roland BN-20 and BN-20A are both a printer and cutter. The machine first prints...

...then cuts around the image. The printing is relatively fast, but the cutting is slow.

The DTF model prints the color layer first, then prints the white layer in a second pass on DTF film. There is no cutting in DTF printing...but the printing is relatively slow.

Post Printing and Cutting Process

Transfers, decals and stickers print and cut on the Roland BN-20 will need to be weeded and transferred then applied to their final surface - sometimes using a mask.

DTF transfers printed on the Roland BN-20D do not need to be weeded, however a DTF powder needs to be applied to the wet ink.

The powder is then cured in a curing oven or heat press to create a glue or adhesive that will then melt when applied to the garment with a heat press or iron either immediately or at a later time.

Here's a quick reference guide on the differences between the Roland BN-20 vs the BN-20D.

Want to see the Roland BN-20D printing DTF Transfers or interested in info on how to do the initial BN-20D set up? Check out my videos on Youtube and more Roland DTF tutorials here on Silhouette School Blog.

Interested in Roland DTF Printer Bundles? Check out the BN-20D bundle options here when they become available...and don't forget to add ink (and I'd recommend a stand, DTF film, powder, a curing oven and air filter too) Until then...sign up to get updates on BN-20D pre orders, tutorials and updates!

Note: This post may contain affiliate links. By clicking on them and purchasing products through my links, I receive a small commission. That's what helps fund Silhouette School so I can keep buying new Silhouette-related products to show you how to get the most out of your machine!

Get Silhouette School lessons delivered to your email inbox! Select Once Daily or Weekly.

.png)

Hello! Which printer prints the most wash resistant transfer? Thanks

ReplyDelete