Besides using the correct amount of time, temperature and pressure when it comes to pressing HTV, knowing whether to peel off the carrier sheet hot or cold is an important component to getting a successful press.

In this tutorial, we'll explain the difference between hot peel and cold peel HTV and how to know when to do which.

For this project, we cut and weeded two designs into HTV - one is a hot peel HTV, and the other is a cold peel HTV.

The designs we used for this HTV transfer can be found in the Fall Farmhouse Font and SVG Bundle at So Fontsy.

What's the difference between hot peel and cold peel HTV?

The terms "hot peel" and "cold peel" HTV refer to when you should remove the HTV's carrier sheet after pressing. With "cold peel" HTV, you want to wait until the HTV has cooled, and then remove the carrier sheet.

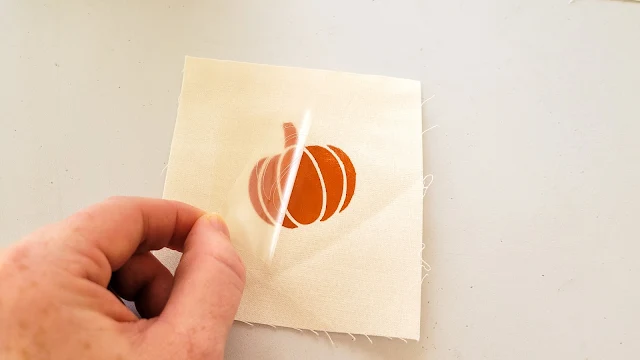

With "hot peel" HTV, you don't need to wait until the HTV is cool to remove the carrier sheet - you can remove it right after pressing.

You may also come across the term "warm peel" which usually means waiting 5 - 15 seconds after pressing to remove the carrier sheet.

Why are some HTVs hot peel and some are cold peel?

With certain types of HTV, the product may need additional time during the cooling period for the HTV's adhesive to adhere to the surface.

If you try to hot peel an HTV that's meant to be cold peeled, it will likely stick to the carrier sheet, wrinkle or curl as you begin to pull away the carrier sheet. If that happens immediately place the carrier sheet back down and wait until the vinyl cools.

Then begin peeling from another area of the carrier sheet - ideally the opposite side.

How to know if an HTV is a hot or cold peel?

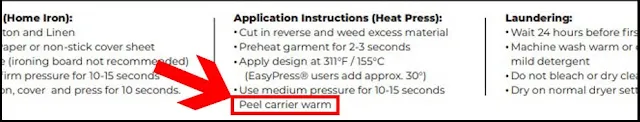

The short answer is - check with the manufacturer. The manufacturer of the HTV will let you know how to use their product. They should not only provide instructions for the recommended time, temperature, and pressure to press their HTV, but also whether you should peel the carrier sheet off hot or cold. You can usually find this information with the HTV's packaging and/or on their website.

What if you don't know who the manufacturer is?

If you have a piece of HTV and are unsure who the manufacturer is and therefore cannot check with them, the best way to find out is to do your own test.

Cut a couple small pieces of the HTV and press both onto a scrap piece of material. Then, peel one carrier sheet cold and peel the other hot and see which one does better.

We did a "hot peel" with this HTV, and it adhered perfectly.

In this case, put the carrier sheet back down, repress, then wait for the HTV to cool. Then, remove the carrier sheet.

In general though, most HTV can be peeled cold (or warmish), so if you're unsure, then that is probably your best bet.

On this apron, we used 2 different kinds of HTV - Siser Brick (black) and Siser Easyweed (orange).

To learn more about how to press HTV onto an apron, check out the following blog post over on the So Fontsy blog.

You can also grab the HTV design we pressed on this apron in the Fall Farmhouse Font and SVG Bundle at So Fontsy.

Note: This post may contain affiliate links. By clicking on them and purchasing products through my links, I receive a small commission. That's what helps fund Silhouette School so I can keep buying new Silhouette-related products to show you how to get the most out of your machine!

Get Silhouette School lessons delivered to your email inbox! Select Once Daily or Weekly.

.jpg)

.png)

No comments

Thanks for leaving a comment! We get several hundred comments a day. While we appreciate every single one of them it's nearly impossible to respond back to all of them, all the time. So... if you could help me by treating these comments like a forum where readers help readers.

In addition, don't forget to look for specific answers by using the Search Box on the blog. If you're still not having any luck, feel free to email me with your question.