Now that I have both an Uninet iColor 560 White Toner Printer and a Roland BN-20A...I am getting A LOT of questions about which one is "better". It's not an easy question to answer because they are two totally different machines!

Although if you ask in the respective Facebook groups...it may seem to be an easy decision based on just how adamant users of the respective printers are that "theirs" is hands-down, no-question better, more versatile, better quality, the top pick over the other.

The truth is I totally understand that for most crafters-turned-at-home small businesses it's a choice to get one over the other due to price and space....so let me help you decide between the BN-20A vs the Uninet iColor 560 White Toner printer... from someone who has both and has no allegiance one way or the other.

My only goal here is to help you make an informed decision for your growing business..and then help you learn whichever machine - BN-20A or Uninet iColor 560 - you decide to invest in.

While price and size are big factors - they're not the only factors when it comes to investing in your at home business. It's MOST important to consider the features of each machine in combination with the MAIN product your business offers.

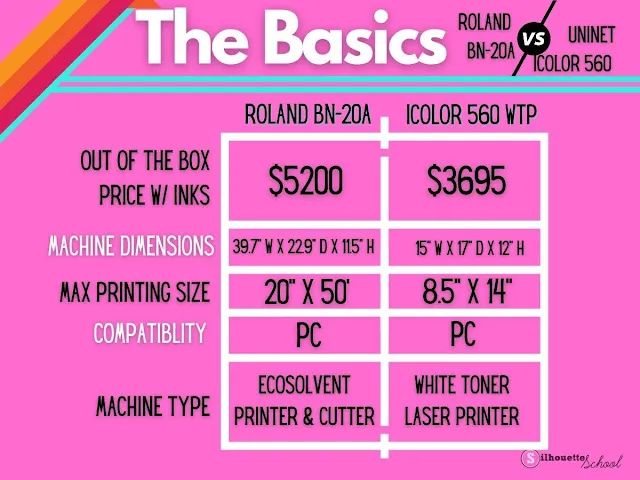

We'll get to all of that but let's start with a side by side comparison by the numbers.

Roland BN-20A vs Uninet iColor 560

When you look at the two machines side by side you can see the differences on paper immediately. The Uninet iColor 560 is a desktop size laser printer (only- no cutting) that can print white, but at smaller sizes.

The Roland BN-20A is considered a "desktop" eco-solvent CMYK printer and cutter in one that can cut up to 20" wide and 50 feet long, but can't print white.

The original BN-20 with a higher price tag can print white and metallics.

Roland BN-20A vs iColor 560 Machine Size

I say the Roland BN-20A is "considered" a desktop because it has a relatively large footprint compared to the iColor 560. Here's a comparison with me standing next to each so you can get an idea.

Still they're both sized for the at-home business. If space is a factor...consider the difference.

BN-20A vs iColor Features Comparison

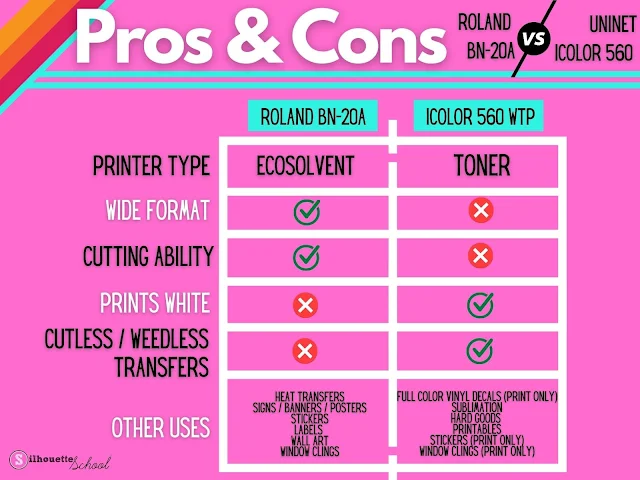

Now that price and size are out of the way let's take look at the features of the BN-20A vs iColor 560 and consider which is BEST for you!

Usually small businesses growing up from Silhouette or Cricut get to this point because they run into limitations with vinyl, heat transfer vinyl and sublimation. Or in the case of sticker and invitation-type businesses, they find the need to print white to offer more products.

Deciding between the iColor 560 White Toner Printer and the Roland BN-20A Printer/Cutter you have to ask yourself one or both of these questions:

What's the core of my business?

Where do I MOST want to grow my business?

If the answer is you're mainly an adhesive vinyl or sticker shop or you do larger volume full color vinyl or HTV transfers the Roland BN-20A is a great choice.

If you are mainly a t-shirt and garment shop that specializes in customs and does single or low number runs and you want to be able to produce ready-to-press, no cut, no weed transfers for all types and colors of garments - especially dark shirts - the Uninet iColor 560 White Toner Printer is a great choice.

The good news is neither of the machines is limited to just its core competency - they can both do a lot more - and there is crossover.

You should also consider that the BN-20 can print heat transfers on materials that the iColor can't like glitter heat transfer.

The iColor 560, because it can print white, can print on clear, light and dark sticker and label sheets, print full color vinyl decals, window clings, transfers for hard goods, dark and light papers..and even create sublimation transfers with speciality sublimation toners.

Because it uses toner you can also create stunning foil prints by adding foil after printing.

Pros and Cons

I have yet to find a printer or cutter that will do everything - which means each has its own list of pros and cons and the iColor 560 and Roland BN-20A are no exception.

Roland BN-20A Pros and Cons

The biggest benefits of the Roland BN-20A over the iColor 560 are the wide format size (volume), the ability to print and cut, and the eco solvent ink. It creates bright, colorful, vibrant transfers and vinyl stickers without the need for layering or worrying. It can take several hours to setup the Roland BN-20 but once you do the learning curve is relatively small.

The biggest drawbacks are it cannot print white and it's relatively slow to both print and cut. The printing and cutting time is hands off so you can still be productive while waiting. In addition, there is still weeding involved and when printing heat transfers they are solid, however there are various material options which will allow you to get a softer feel when the transfer is applied to a garment. The Roland BN-20A also does hard cut lines so designs with faded out edges just aren't ideal.

The Roland also has more maintenance due to the ink. It needs to be left plugged in and powered on so it can go through the automatic cycling every 8 hours.

Uninet iColor 560 Pros and Cons

The biggest benefits of the iColor 560 vs the Roland BN-20 is it can print white and it can print ready-to-press heat transfers which means no cutting and no weeding. The iColor is a very low maintenance machine and requires no regular maintenance or special care.

The biggest downside though is the small print size which you can be somewhat overcome with the Smartcut software for heat transfers (only), the steep learning curve, and that it's exclusively a printer -albeit a versatile one. To cut you'd have to add registration marks in another program and use another cutting machine, like a Silhouette CAMEO to contour cut vinyl decals, stickers, and labels.

In addition, the materials can be pricey per sheet especially for the materials that offer more vibrant colors and better stretch.

Another thing to consider with the iColor White Toner Printer is the potential for cracking. To help limit transfers from cracking you'll need to make some modifications to the design itself, use high quality transfer and adhesive sheets, and instruct the end user on best practices for laundering. Large solid areas of a transfers contribute to cracking. To limit this, you can remove the shirt color from the design.

In this example, all of the black was removed from the original design so the black shirt would show through as black.

On designs where knocking out the shirt color still doesn't offer enough space in the design you'll need to rasterize to add small holes or lines in the transfer to allow the design to breath to help limit and avoid cracking.

Cracking in white toner transfers is not uncommon, but can be avoided if you prepare the design and launder it correctly.

To be honest, I skip both of these options at all costs because I do not like the look especially in the high contrast areas like the white on black. NOTE: These examples use the default settings, but you can make smaller lines and holes so they are less noticeable.

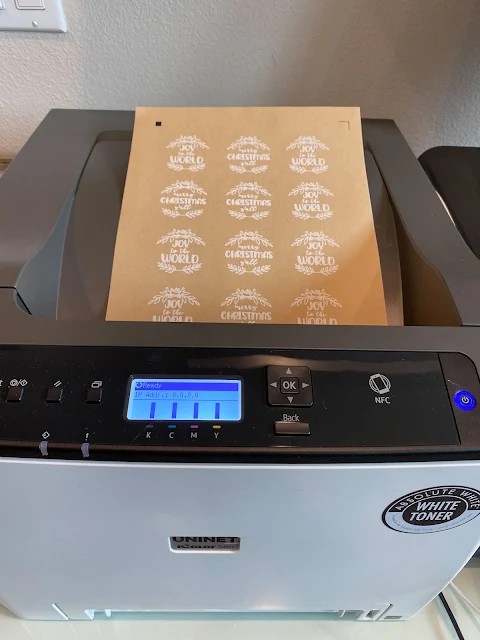

iColor 560 White Toner Printer vs Roland BN-20A Printing Method

The type of printing is also very different between the two machines. Let's look at a few examples.

Creating Heat Transfers: iColor 560 vs BN-20A

To create a heat transfer with the iColor 560, the printer lays down toner onto a clear transfer sheet. The adhesive is applied in a second step called "marrying." After that, the transfer can then be applied immediately and directly to the shirt. There is no cutting or weeding needed.

The Roland BN-20A can also create HTV transfers but it's printing permanent eco solvent ink directly onto a white HTV material, like Siser heat transfer vinyl, then contour cutting around the solid design to create the transfer. The HTV needs to be weeded and a mask is needed to transfer the cut HTV onto the substrate where it's heat pressed on.

Because of the way each prints, transfers from both can be used on dark garments and cottons unlike sublimation which is limited to light colored polyester garments.

Creating Vinyl Decals: iColor 560 vs BN-20A

To create a vinyl decal, stickers or labels on the iColor 560 the design size would have to be limited to 8.5" x 14" and registration marks for the cut line would need to be added in another program, like Silhouette Studio, and printed along with the decal.

The vinyl decal or stickers would be printed on the iColor vinyl material then have to be cut on a separate machine like the Silhouette CAMEO.

The benefit to using the iColor 560 for stickers and labels is - because of the ability to add a white underprint, users can print stickers with white text on colored, black, or clear sticker paper.

For small size stickers and decals or small volume runs the iColor 560 when paired with a Silhouette CAMEO for the cutting is perfect.

To create a vinyl decal, stickers or labels on the Roland BN-20A the design size could be as large as 20" wide almost infinitely long or you an could make multiple copies of the same sticker simultaneously saving time.

Not only will the BN-20A print scratch resistant, fade resistant vinyl decal, it will also cut it in a second pass - all on the same machine. Laminating vinyl stickers is recommended for longer outdoor use.

Contour cut lines need to be added and this has to be done in a program like Adobe Illustrator. It's an easy enough process, but the software needed to add the cut lines is an added, on-going expensive so just be aware of that.

The BN-20A can also print and cut stickers and labels but only on white material given that the BN-20A does not have a white ink cartridge. To get a look like this sticker, the design itself would have to be filled with black and printed onto white sticker material.

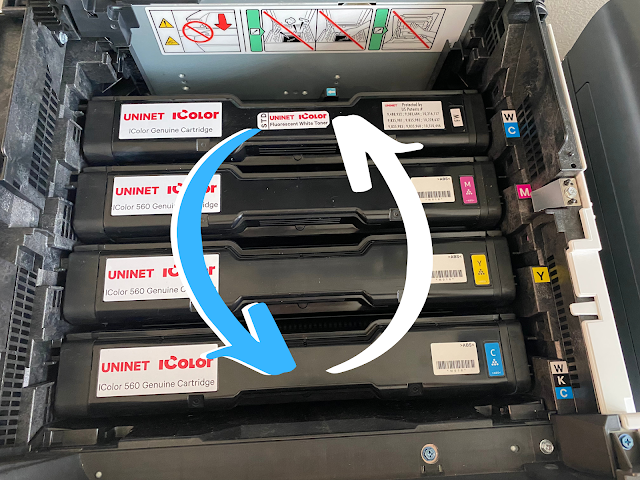

iColor 560 White Toner vs Roland BN-20 Ecosolvent Ink

Aside from the size, price, and features the printing method is also different between the iColor 560 and the BN-20A. Forgive the the heading "ink", for the sake of this graphic, as the iColor 560 uses toner not ink.

Both the iColor 560 and the Roland BN-20 both use 220ml / cc of toner/ink so the cartridge volume is the same.

The 4-cartridge capacity iColor 560 is a white toner printer that can print white under and over other colors depending on the application which is what allows the full color heat transfers to be applied to dark color garments.

Toner is powder allowing the cartridges and cartridge configuration to be switched at any time with little to no maintenance and high yield (refill cartridges yield 7k pages at 5% coverage).

The Roland BN-20A is a printer and cutter that uses 220cc volume, fast drying eco-solvent ink cartridges which are not only permanent but also scratch and fade resistant. This is why it's ideal for vinyl stickers and window clings.

It too can be used on a wide variety of materials including vinyl stickers, label stickers, window clings, heat transfers, and signs/banners. The Roland BN-20A can not print white and the inks are not included with the machine (which is why I listed the ink price above).

Which is Better BN20 vs White Toner

The answer to should I get a BN-20A or an iColor 560 is really going to depend on you, your business, and your needs. Pick the one that BEST fits the core needs now! Use it to grow your business and then invest that into the other machine if you ultimate decide you need both.

I have tutorials and videos on how to use both so you can feel confident that you'll have the support you need no matter which machine you go with!

Get Silhouette School lessons delivered to your email inbox! Select Once Daily or Weekly.

.png)

No comments

Thanks for leaving a comment! We get several hundred comments a day. While we appreciate every single one of them it's nearly impossible to respond back to all of them, all the time. So... if you could help me by treating these comments like a forum where readers help readers.

In addition, don't forget to look for specific answers by using the Search Box on the blog. If you're still not having any luck, feel free to email me with your question.