When it comes to making full color t shirt transfers there are a few different ways you can do it - it all depends on the equipment you have and the t shirt itself.

Let's take a look at the differences between sublimation vs white toner transfers and the pros and cons of each when it comes to making t-shirts specifically.

Sublimation printers and White Toner printers can both print custom t-shirt transfers, however the process is vastly different for both.

Having both the Uninet iColor 560 White Toner Printer and the Sawgrass SG400 sublimation printer, I have seen the pro and cons of all of these printers when it comes to making t shirts.

Let's look at the similarities first:

- Transfers Require NO Cutting or Weeding

- Prints Full Color Images

- Prints Standard 8.5 x 11"

- Requires Heat Press for Transfer Application

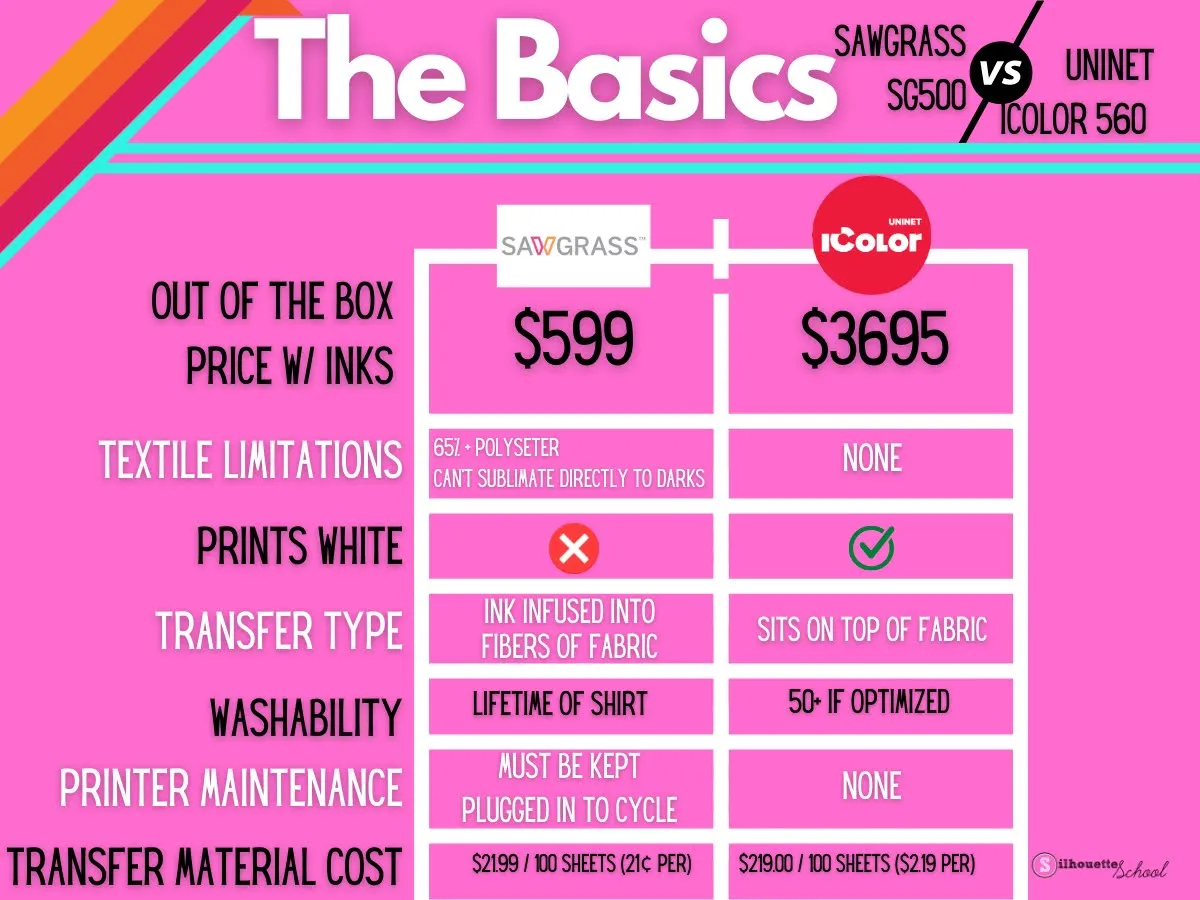

The list of differences is much longer with everything from the start up price to the type of ink / toner to the speed of the process to what type of t-shirt can be used. Here's a quick look then we'll go into detail.

Sublimation vs White Toner Printer for T Shirts: Printer Price Comparison

There's no question that the price of an 8.5" wide sublimation printer is significantly less than that of a desktop white toner printer. However there's a reason for that price differential.

The Sawgrass SG500 comes with a 21mL starter set of CMYK sublimation inks. The replacement ink cartridges are 32mL with an estimated 300 page yield. Sublimation printers can sublimate hard and soft goods with sublimation inks only.

The Uninet iColor White Toner Printer which includes five "starter" toner cartridges for CMYK plus white prints about 1000 pages at 5% coverage or 100 pages at 40% coverage. The replacement cartridges are a 7,000 page yield at 5% coverage. However, keep in mind the Uninet iColor White Toner printer is a more versatile printer as it can do a lot more than t shirt transfers. I can also do hard goods, full color vinyl decals, paper, stickers, and foil.

Print Color Comparison: White Toner Printer vs Sublimation

The additional ability to print white is also where the increased price of the white toner printer comes in. The ability to print white means you can create t shirt transfers that not only include white, but the white can be used as a base for other colors so that white toner transfers can be placed on any color shirt and the colors can really pop!

Sublimation transfers can only be transferred directly to light colored shirts because the ink will not be visible otherwise.

While the process to print white with the Uninet iColor 560 happens during a single pass print of the transfers, applying sublimation transfers to darker color shirts means you either need to bleach the shirt first (to make a white / light area) or you need to sublimate onto another material such as white flock or glitter white heat transfer vinyl instead of directly to the shirt.

The side by side image below should give you a better idea of sublimation vs white toner transfers using the exact same design from So Fontsy. (The black shirt is a white toner printer transfer while the other is sublimated.)

T-Shirt and Textile Types for White Toner Printer vs Sublimation

White toner printer transfers can be directly applied to basically any type of textile and blend including cotton, polyester, and nylon..and of course any color.

Sublimation transfers can only be directly applied to fabrics that are at least 65% polyester. Using fabrics with a lower polyester count will result in the colors being muted. In addition the garment needs to be a light color - or made a light color through bleaching.

Application Process: Sublimation vs White Toner Printer Transfers

How to Print and Apply a Sublimation Transfer

Assuming the t shirt is sublimation-ready, the application process for sublimation is fast and simple. The image will need to be printed through the sublimation printer's print manager, but there's no other design set up needed.

The application process is as simple as print from the sublimation printer and press at 400 degrees for 60 seconds.

How to Print and Apply a Sublimation Transfer

The application process for white toner printer is a bit more extensive and undoubtedly takes more time. The design needs to be prepared in the iColor ProRip software to do things like removing the color of the shirt from the design and adding rasterization. The amount of time this takes depends on the design itself - but let's call it 10 minutes.

The transfer can then be printed from the ProRip software directly to the White Toner Printer. It usually takes at least two minutes for the printer to process the request and then print the transfer (This time is sped up when printing multiple transfers of the same image.)

Once printed, the adhesive needs to be applied to the back of the transfer. This is done through a process called "marrying." The adhesive sheet and the printed transfer sheet must be pressed together in the heat press for 120 seconds during this process. The excess adhesive sheet is then removed leaving the adhesive behind only on the printed areas of the transfer.

The transfer can then be applied to the shirt. The pressing time for this step is 30 seconds. Once pressed, the transfer needs to cool completely (ideally 5 minutes) before the transfer sheet is pulled away leaving the transfer on the t shirt.

The final step is to press the shirt again to remove the shine and press it deeper into the fabrics of the shirt for about 20 seconds.

Washability: Sublimation Vs White Toner Printer Transfers

There is no risk of cracking or peeling with sublimated garments as the ink is transferred into the fabrics of the shirt. Washability is very good with the only real risk being that a lower polyester count can cause the colors in the image to fade with washing. The higher the polyester count, the lower the risk.

Unlike sublimation, white toner transfers sit on top of the shirt as opposed to being infused into the fabric's fibers. Similar to HTV, direct to film, and screen printing this leads to a higher risk of cracking or peeling if not prepared and laundered correctly.

Depending on how the image/design was optimized and the specific type of transfer material used, White Toner transfers have a washability up to 50 cycles. The colors will not fade or bleed, but cracking can occur if the design is not prepared correctly or if the optimal transfer material is not used.

To prevent cracking and get the best washability with ready to press transfers, the image must be optimized in the ProRip through rasterizing. This and and should include removing the color of the shirt to create breathable areas), using a limited amount of white under base, and adding tiny holes or lines in the design to allow for stretch or adding natural breaks in the design like distressing.

So what's the best way to make t shirts: Sublimation or White Toner?

There's not an easy answer for this other than: it depends. Each type of printer and application has its own pros and cons so it really will depend on what's most important to you and your small business or hobby craft.

Get Silhouette School lessons delivered to your email inbox! Select Once Daily or Weekly.

.png)

No comments

Thanks for leaving a comment! We get several hundred comments a day. While we appreciate every single one of them it's nearly impossible to respond back to all of them, all the time. So... if you could help me by treating these comments like a forum where readers help readers.

In addition, don't forget to look for specific answers by using the Search Box on the blog. If you're still not having any luck, feel free to email me with your question.